THE BASICS OF FIBER OPTIC CABLE

(Single-mode multi-mode)

a Tutorial

BRIEF OVER VIEW OF FIBER OPTIC CABLE ADVANTAGES OVER COPPER:

• SPEED: Fiber optic networks operate at high

speeds - up into the gigabits

• BANDWIDTH: large carrying capacity

• DISTANCE: Signals can be transmitted further

without needing to be "refreshed" or strengthened.

• RESISTANCE: Greater resistance to electromagnetic

noise such as radios, motors or other nearby cables.

• MAINTENANCE: Fiber optic cables costs much less to

maintain.

In recent years it has become apparent that fiber-optics are steadily replacing

copper wire as an appropriate means of communication signal transmission. They

span the long distances between local phone systems as well as providing the

backbone for many network systems. Other system users include cable television

services, university campuses, office buildings, industrial plants, and electric

utility companies.

A fiber-optic system is similar to the copper wire system

that fiber-optics is replacing. The difference is that fiber-optics use light

pulses to transmit information down fiber lines instead of using electronic

pulses to transmit information down copper lines. Looking at the components in a

fiber-optic chain will give a better understanding of how the system works in

conjunction with wire based systems.

At one end of the system is a transmitter. This is the

place of origin for information coming on to fiber-optic lines. The transmitter

accepts coded electronic pulse information coming from copper wire. It then

processes and translates that information into equivalently coded light pulses.

A light-emitting diode (LED) or an injection-laser diode (ILD) can be used for

generating the light pulses. Using a lens, the light pulses are funneled into

the fiber-optic medium where they travel down the cable. The light (near

infrared) is most often 850nm for shorter distances and 1,300nm for longer

distances on Multi-mode fiber and 1300nm for single-mode fiber and 1,500nm is

used for for longer distances.

Think of a fiber cable in terms of very long cardboard

roll (from the inside roll of paper towel) that is coated with a mirror on the

inside.

If you shine a flashlight in one end you can see light come out at the far end - even if it's

been bent

around a corner.

Light pulses move easily down the fiber-optic line because

of a principle known as total internal reflection. "This principle of total

internal reflection states that when the angle of incidence exceeds a critical

value, light cannot get out of the glass; instead, the light bounces back in.

When this principle is applied to the construction of the fiber-optic strand, it

is possible to transmit information down fiber lines in the form of light

pulses. The core must a very clear and pure material for the light or in most

cases near infrared light (850nm, 1300nm and 1500nm). The core can be Plastic

(used for very short distances) but most are made from glass. Glass optical

fibers are almost always made from pure

silica, but some other materials, such as

fluorozirconate,

fluoroaluminate, and

chalcogenide glasses, are used for longer-wavelength infrared applications.

There are three types of fiber optic cable commonly used: single mode,

multimode and plastic optical fiber (POF).

Transparent glass or plastic fibers which allow light to be guided from one end to the other with minimal loss.

Fiber optic cable functions as a "light guide,"

guiding the light introduced at one end of the cable through to

the other end. The light source can either be a light-emitting

diode (LED)) or a laser.

The light source is pulsed on and off, and a light-sensitive

receiver on the other end of the cable converts the pulses back

into the digital ones and zeros of the original signal.

Even laser light shining through a fiber optic cable is

subject to loss of strength, primarily through dispersion and

scattering of the light, within the cable itself. The faster the

laser fluctuates, the greater the risk of dispersion. Light

strengtheners, called repeaters, may be necessary to refresh the

signal in certain applications.

While fiber optic cable itself has become cheaper over

time - a equivalent

length of copper cable cost less per foot but not in capacity. Fiber optic cable connectors and the

equipment needed to install them are still more expensive than their

copper counterparts.

Single Mode cable is a single stand

(most applications use 2 fibers) of glass fiber with a

diameter of 8.3 to 10 microns that has one mode of transmission.

Single Mode Fiber with a relatively narrow diameter, through which only one mode

will propagate typically 1310 or 1550nm. Carries higher bandwidth than multimode fiber, but requires a

light source with a narrow spectral width. Synonyms mono-mode optical fiber,

single-mode fiber, single-mode optical waveguide, uni-mode fiber.

Single Modem fiber is used in many applications where data

is sent at multi-frequency (WDM Wave-Division-Multiplexing) so only one cable is

needed - (single-mode on one single fiber)

Single-mode

fiber gives you a higher transmission rate and up to 50 times more distance than

multimode, but it also costs more. Single-mode fiber has a much smaller core

than multimode. The small core and single light-wave virtually

eliminate any distortion that could result from overlapping light pulses,

providing the least signal attenuation and the highest transmission speeds of

any fiber cable type.

Single-mode optical fiber is an optical fiber in which only the lowest order

bound mode can propagate at the wavelength of interest typically 1300 to 1320nm.

jump to single mode fiber

page

Multi-Mode cable has a little bit bigger

diameter,

with a common diameters in the 50-to-100 micron range for the light carry component

(in the US the most common size is 62.5um). Most applications in which

Multi-mode fiber is used, 2 fibers are used (WDM is not normally used on

multi-mode fiber). POF is a newer plastic-based cable which promises performance similar to

glass cable on very short runs, but at a lower cost.

Multimode fiber

gives you high bandwidth at high speeds (10 to 100MBS - Gigabit to 275m to 2km) over medium distances. Light waves are

dispersed into numerous paths, or modes, as they travel through the cable's core

typically 850 or 1300nm. Typical multimode fiber core diameters are 50, 62.5, and 100 micrometers.

However, in long cable runs (greater than 3000 feet [914.4 meters), multiple paths

of light can cause signal distortion at the receiving end, resulting in an

unclear and incomplete data transmission so designers now call for single mode

fiber in new applications using Gigabit and beyond.

The use of fiber-optics was generally not available until 1970 when Corning

Glass Works was able to produce a fiber with a loss of 20 dB/km. It was

recognized that optical fiber would be feasible for telecommunication

transmission only if glass could be developed so pure that attenuation would be

20dB/km or less. That is, 1% of the light would remain after traveling 1 km.

Today's optical fiber attenuation ranges from 0.5dB/km to 1000dB/km depending on

the optical fiber used. Attenuation limits are based on intended application.

The applications of optical fiber communications have increased at a rapid

rate, since the first commercial installation of a fiber-optic system in 1977.

Telephone companies began early on, replacing their old copper wire systems with

optical fiber lines. Today's telephone companies use optical fiber throughout

their system as the backbone architecture and as the long-distance connection

between city phone systems.

Cable television companies have also began integrating fiber-optics into

their cable systems. The trunk lines that connect central offices have generally

been replaced with optical fiber. Some providers have begun experimenting with

fiber to the curb using a fiber/coaxial hybrid. Such a hybrid allows for the

integration of fiber and coaxial at a neighborhood location. This location,

called a node, would provide the optical receiver that converts the light

impulses back to electronic signals. The signals could then be fed to individual

homes via coaxial cable.

Local Area Networks (LAN) is a collective group of computers, or computer

systems, connected to each other allowing for shared program software or data

bases. Colleges, universities, office buildings, and industrial plants, just to

name a few, all make use of optical fiber within their LAN systems.

Power companies are an emerging group that have begun to utilize fiber-optics

in their communication systems. Most power utilities already have fiber-optic

communication systems in use for monitoring their power grid systems.

jump to

Illustrated Fiber Optic

Glossary pages

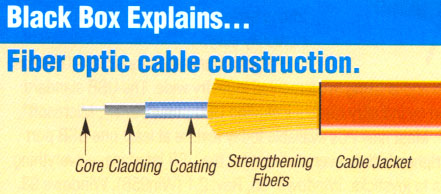

Fiber

by John MacChesney - Fellow at

Bell Laboratories, Lucent Technologies

Some 10 billion digital bits can

be transmitted per second along an optical fiber link in a

commercial network, enough to carry tens of thousands of

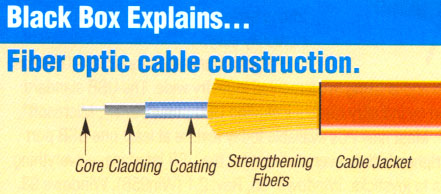

telephone calls. Hair-thin fibers consist of two concentric

layers of high-purity silica glass the core and the cladding,

which are enclosed by a protective sheath. Light rays modulated

into digital pulses with a laser or a light-emitting diode move

along the core without penetrating the cladding.

The light stays confined to the

core because the cladding has a lower refractive index—a

measure of its ability to bend light. Refinements in optical

fibers, along with the development of new lasers and diodes, may

one day allow commercial fiber-optic networks to carry trillions

of bits of data per second.

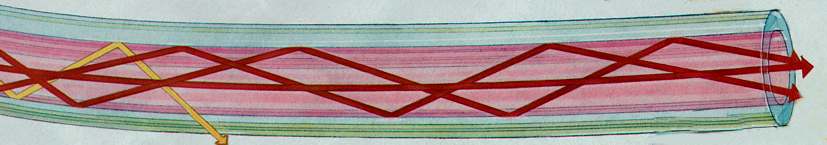

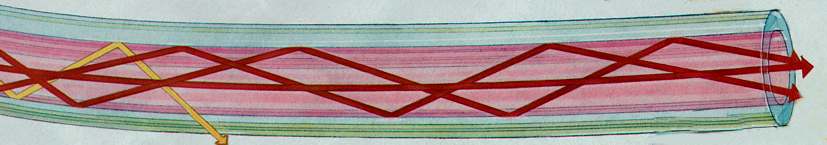

Total internal refection

confines light within optical fibers (similar to looking down a

mirror made in the shape of a long paper towel tube). Because the

cladding has a lower refractive index, light rays reflect back

into the core if they encounter the cladding at a shallow angle

(red lines). A ray that exceeds a certain "critical"

angle escapes from the fiber (yellow line).

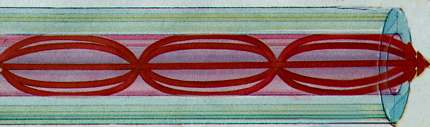

STEP-INDEX MULTIMODE FIBER

has a large core, up to 100 microns in diameter. As a result,

some of the light rays that make up the digital pulse may travel

a direct route, whereas others zigzag as they bounce off the

cladding. These alternative pathways cause the different

groupings of light rays, referred to as modes, to arrive

separately at a receiving point. The pulse, an aggregate of

different modes, begins to spread out, losing its well-defined

shape. The need to leave spacing between pulses to prevent

overlapping limits bandwidth that is, the amount of information

that can be sent. Consequently, this type of fiber is best suited

for transmission over short distances, in an endoscope, for

instance.

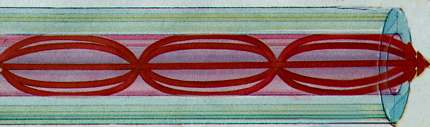

GRADED-INDEX MULTIMODE FIBER

contains a core in which the refractive index diminishes

gradually from the center axis out toward the cladding. The

higher refractive index at the center makes the light rays moving

down the axis advance more slowly than those near the cladding.

Also, rather than zigzagging off the cladding, light in the core

curves helically because of the graded index, reducing its travel

distance. The shortened path and the higher speed allow light at

the periphery to arrive at a receiver at about the same time as

the slow but straight rays in the core axis. The result: a

digital pulse suffers less dispersion.

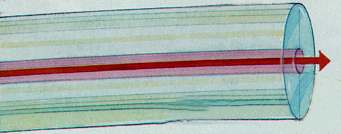

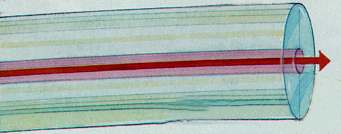

SINGLE-MODE FIBER has a narrow

core (eight microns or less), and the index of refraction between

the core and the cladding changes less than it does for multimode

fibers. Light thus travels parallel to the axis, creating little

pulse dispersion. Telephone and cable television networks install

millions of kilometers of this fiber every year.

BASIC

CABLE DESIGN

1 - Two basic

cable designs are:

Loose-tube cable, used in

the majority of outside-plant installations in North America, and

tight-buffered cable, primarily used inside buildings.

The modular design of

loose-tube cables typically holds up to 12 fibers per buffer tube

with a maximum per cable fiber count of more than 200 fibers.

Loose-tube cables can be all-dielectric or optionally armored.

The modular buffer-tube design permits easy drop-off of groups of

fibers at intermediate points, without interfering with other

protected buffer tubes being routed to other locations. The

loose-tube design also helps in the identification and

administration of fibers in the system.

Single-fiber

tight-buffered cables are used as pigtails, patch cords and

jumpers to terminate loose-tube cables directly into

opto-electronic transmitters, receivers and other active and

passive components.

Multi-fiber tight-buffered

cables also are available and are used primarily for alternative

routing and handling flexibility and ease within buildings.

In a loose-tube cable

design, color-coded plastic buffer tubes house and protect

optical fibers. A gel filling compound impedes water penetration.

Excess fiber length (relative to buffer tube length) insulates

fibers from stresses of installation and environmental loading.

Buffer tubes are stranded around a dielectric or steel central

member, which serves as an anti-buckling element.

The cable core, typically uses aramid yarn,

as the primary tensile strength

member. The outer polyethylene jacket is extruded over the core.

If armoring is required, a corrugated steel tape is formed around

a single jacketed cable with an additional jacket extruded over

the armor.

Loose-tube cables

typically are used for outside-plant installation in aerial, duct

and direct-buried applications.

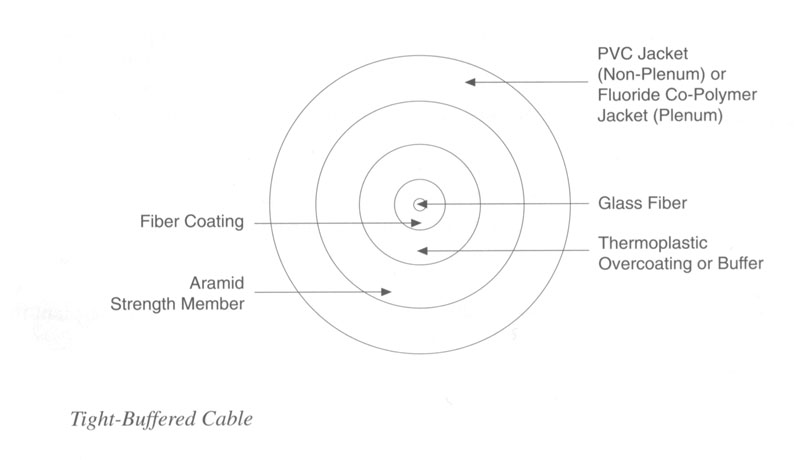

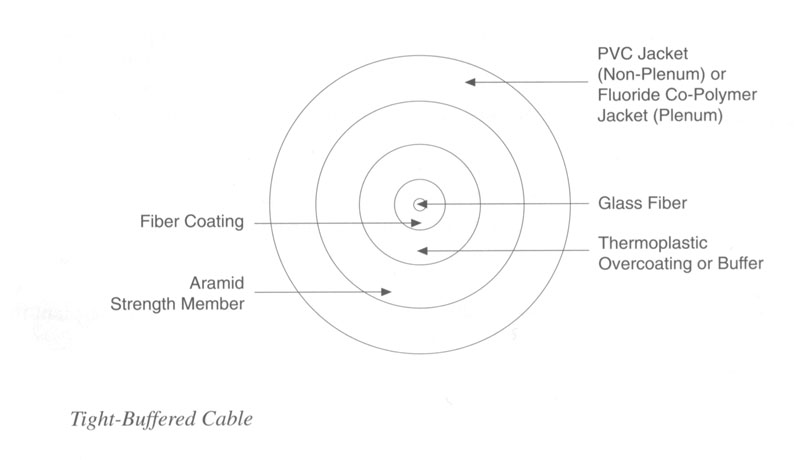

With tight-buffered cable

designs, the buffering material is in direct contact with the

fiber. This design is suited for "jumper cables" which

connect outside plant cables to terminal equipment, and also for

linking various devices in a premises network.

Multi-fiber,

tight-buffered cables often are used for intra-building, risers,

general building and plenum applications.

The tight-buffered design

provides a rugged cable structure to protect individual fibers

during handling, routing and connectorization. Yarn strength

members keep the tensile load away from the fiber.

As with loose-tube cables,

optical specifications for tight-buffered cables also should

include the maximum performance of all fibers over the operating

temperature range and life of the cable. Averages should not be

acceptable.

Connector Types

Gruber Industries

cable connectors

here are some common fiber

cable types

What's the best way to terminate fiber optic cable? That

depends on the application, cost considerations and your own personal

preferences. The following connector comparisons can make the decision

easier.

Epoxy & Polish

Epoxy & polish style connectors were the original fiber optic connectors.

They still represent the largest segment of connectors, in both quantity

used and variety available. Practically every style of connector is

available including ST, SC, FC, LC, D4, SMA, MU, and MTRJ. Advantages

include:

• Very robust. This connector style is based on tried and true technology,

and can withstand the greatest environmental and mechanical stress when

compared to the other connector technologies.

• This style of connector accepts the widest assortment of cable jacket

diameters. Most connectors of this group have versions to fit onto 900um

buffered fiber, and up to 3.0mm jacketed fiber.

• Versions are. available that hold from 1 to 24 fibers in a single

connector.

Installation Time: There is an initial setup time for the field technician

who must prepare a workstation with polishing equipment and an epoxy-curing

oven. The termination time for one connector is about 25 minutes due to the

time needed to heat cure the epoxy. Average time per connector in a large

batch can be as low as 5 or 6 minutes. Faster curing epoxies such as

anaerobic epoxy can reduce the installation time, but fast cure epoxies are

not suitable for all connectors.

Skill Level: These connectors, while not difficult to install, do require

the most supervised skills training, especially for polishing. They are best

suited for the high-volume installer or assembly house with a trained and

stable work force.

Costs: Least expensive connectors to purchase, in many cases being 30 to 50

percent cheaper than other termination style connectors. However, factor in

the cost of epoxy curing and ferrule polishing equipment, and their

associated consumables.

Pre-Loaded Epoxy or No-Epoxy & Polish

There are two main categories of no-epoxy & polish connectors. The first are

connectors that are pre-loaded with a measured amount of epoxy. These

connectors reduce the skill level needed to install a connector but they

don't significantly reduce the time or equipment need-ed. The second

category of connectors uses no epoxy at all. Usually they use an internal

crimp mechanism to stabilize the fiber. These connectors reduce both the

skill level needed and installation time. ST, SC, and FC connector styles

are available. Advantages include:

• Epoxy injection is not required.

• No scraped connectors due to epoxy over-fill.

• Reduced equipment requirements for some versions.

Installation Time: Both versions have short setup time, with pre-loaded

epoxy connectors having a slightly longer setup. Due to curing time, the

pre-loaded epoxy connectors require the same amount of installation time as

standard connectors, 25 minutes for 1 connector, 5-6 minutes average for a

batch. Connectors that use the internal crimp method install in 2 minutes or

less.

Skill Level: Skill requirements are reduced because the crimp mechanism is

easier to master than using epoxy. They provide maximum flexibility with one

technology and a balance between skill and cost.

Costs: Moderately more expensive to purchase than a standard connector.

Equipment cost is equal to or less than that of standard con¬nectors.

Consumable cost is reduced to polish film and cleaning sup-plies. Cost

benefits derive from reduced training requirements and fast installation

time.

No-Epoxy & No-Polish

Easiest and fastest connectors to install; well suited for contractors who

cannot cost-justify the training and supervision required for standard

connectors. Good solution for fast field restorations. ST, SC, FC, LC, and

MTRJ connector styles are available. Advantages include:

• No setup time required.

• Lowest installation time per connector.

• Limited training required.

• Little or no consumables costs.

Installation Time: Almost zero. Its less than 1 minute regardless of number

of connectors.

Skill level: Requires minimal training, making this type of connector ideal

for installation companies with a high turnover rate of installers and/or

that do limited amounts of optical-fiber terminations.

Costs: Generally the most expensive style connector to purchase, since some

of the labor (polishing) is done in the factory. Also, one or two fairly

expensive installation tools may be required. However, it may still be less

expensive on a cost-per-installed-connector basis due to lower labor cost. |

jump to

Calculating fiber loss and

distance

jump to

related

fiber optic equipment pages

jump to

Telebyte

Fiber tutorial pages

(very good write up)

2.

The Fiber Optic Data Communications Link For the Premises Environment

2.1

The Fiber Optic data Communications Link, End-to-End

2.2

Fiber Optic Cable

2.3

Transmitter

2.4

Receiver

2.5

Connectors

2.6

Splicing

2.7

Analyzing Performance of a Link

jump to

The Complete Telebyte

Fiber tutorial pages

ARC Electronics

301-924-7400 EXT 25

arc@arcelect.com